Product introduction:

A600 high-performance vector control inverter adopts advanced current vector control technology. It has full frequency high torque output and fast response, excellent load adaptability, high speed control accuracy and good reliability. It is an ideal choice for high-performance general-purpose inverters that can truly meet higher site requirements.

Product Features:

Superior performance, 4 control modes can be realized

The highest operating frequency HKUST 3000HZ

Automatic slip compensation-more accurate speed

Excellent torque output: 150% rated torque at 3.0HZ (VF control)

0.5HZ180% rated torque (current vector control)

High overload capacity—150% rated torque lasts for 60 seconds

Ultra-low noise, the carrier frequency can be adjusted between 1-16K (set by model)

Timely and reliable control and protection, high system stability

Product Features:

1. Can be equipped with LCD panel, dual-line digital tube panel, single-line digital tube panel

2. Pulse train I/O function

3. Running time and power consumption record

4. Speed and torque control

5. Separate VF control

6. Swing frequency control

7. Fixed length control

8. PID control air energy

9. Communication function

10. The panel has a parameter copy function

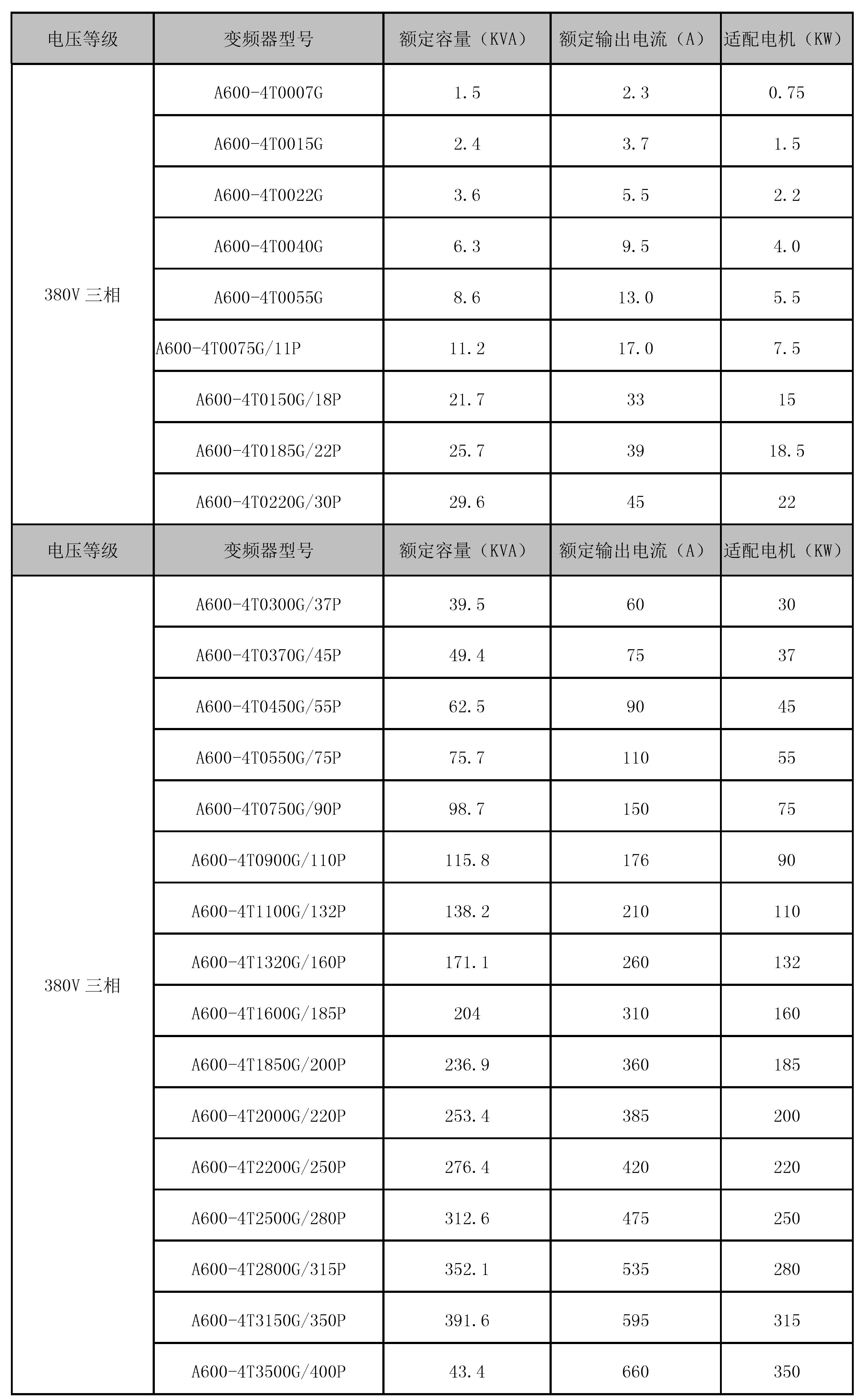

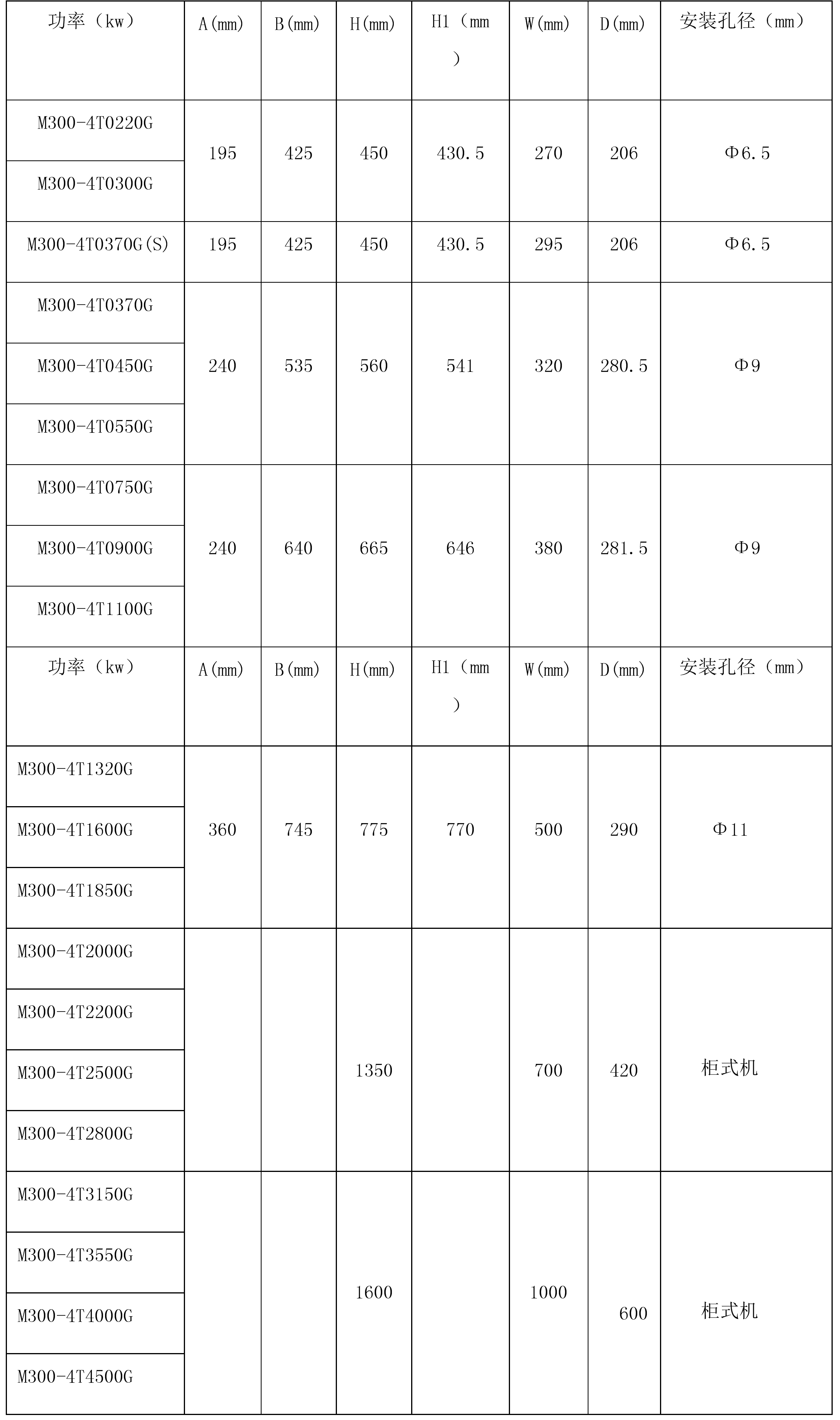

The voltage level of the A600 series inverter is 380V, and the power range of the adapted motor is: 0.75KW~450KW. Model of A600 series inverter

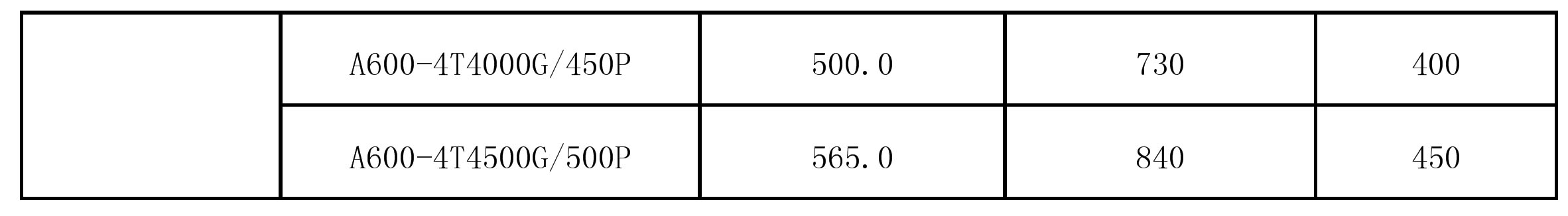

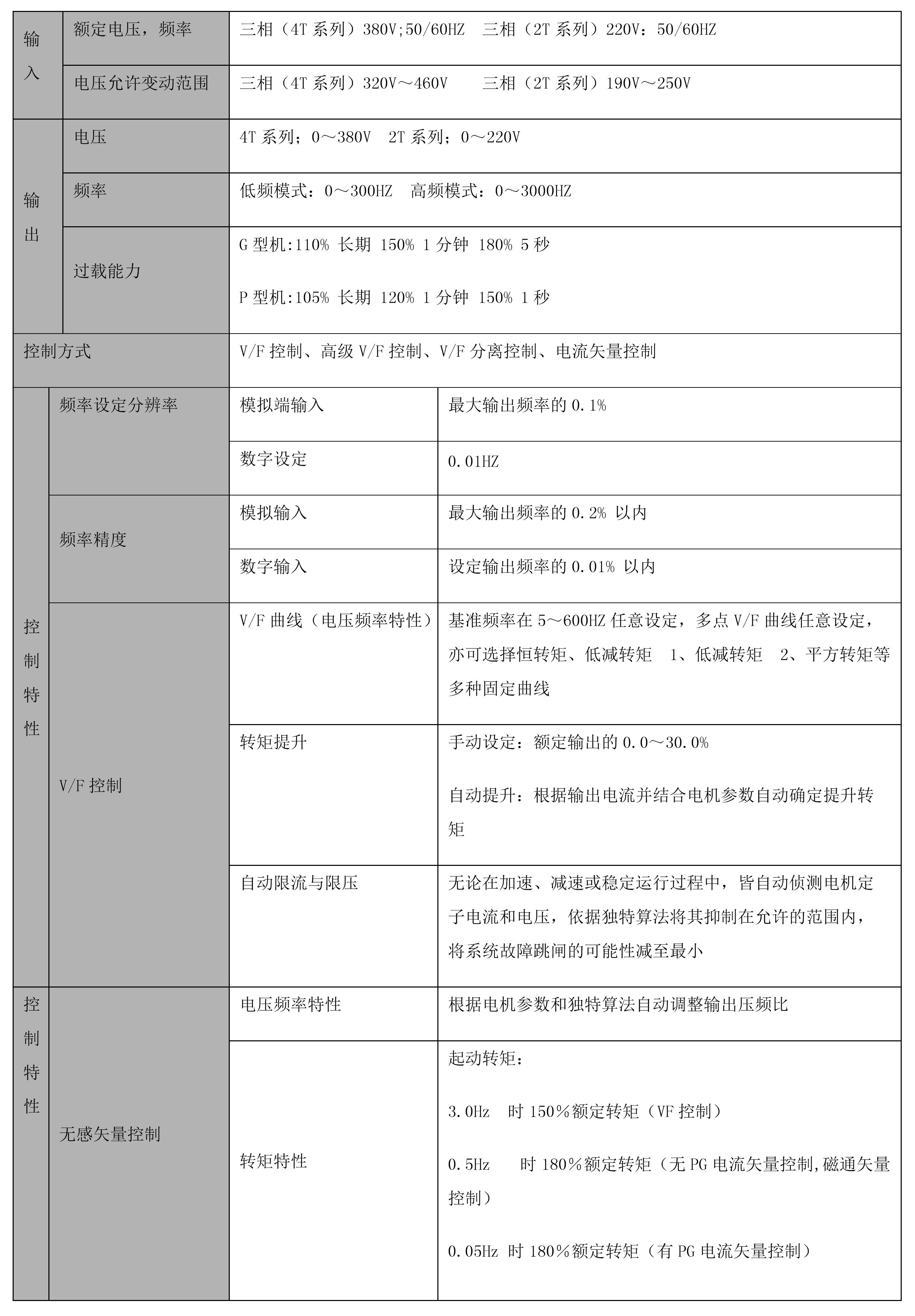

产品技术指标及规格:

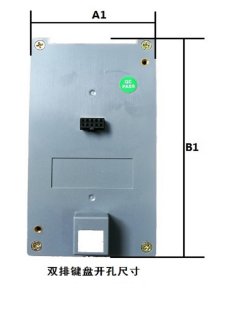

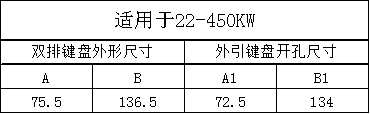

Keyboard outline size and external lead opening size

![]()

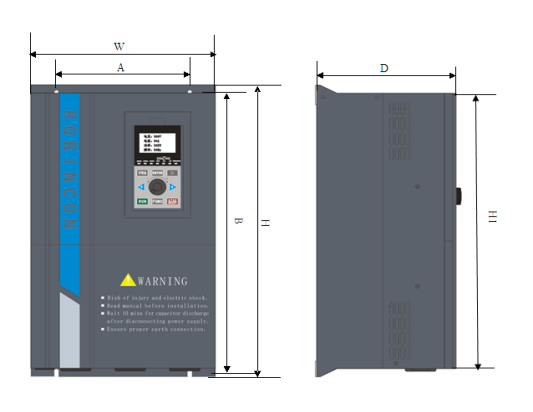

Whole machine structure unit: mm

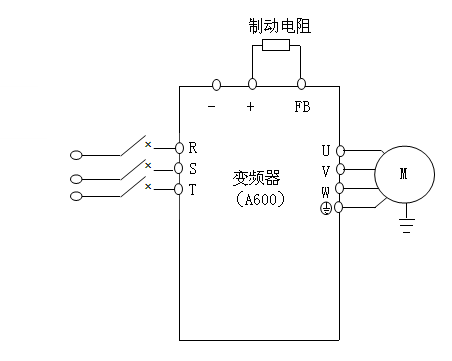

The inverter wiring part is divided into main circuit and control circuit. The user can lift the cover of the output/input terminal, and the main circuit terminal and the control circuit terminal can be seen at this time. The user must connect the wiring circuit correctly according to the figure below.

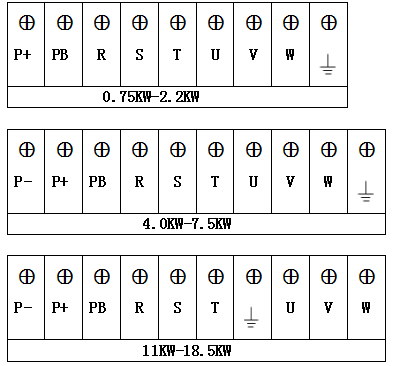

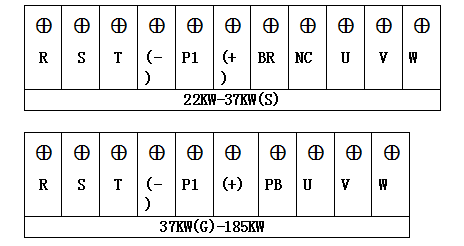

主回路端子配线

主回路端子示意图

主回路端子示意图

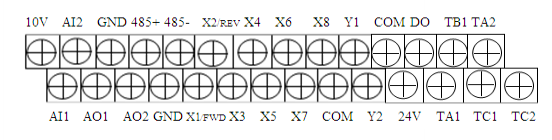

控制回路端子示意图

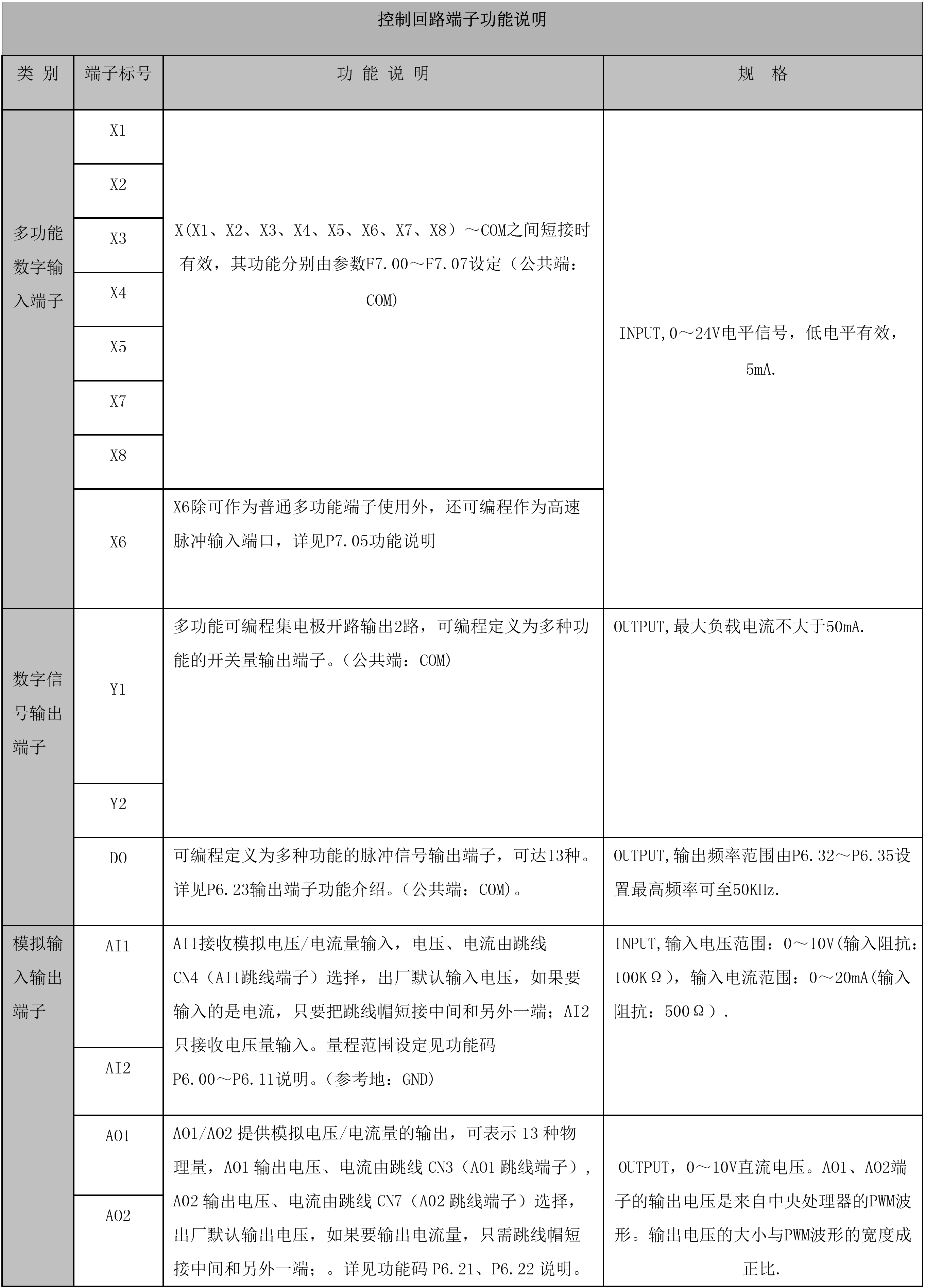

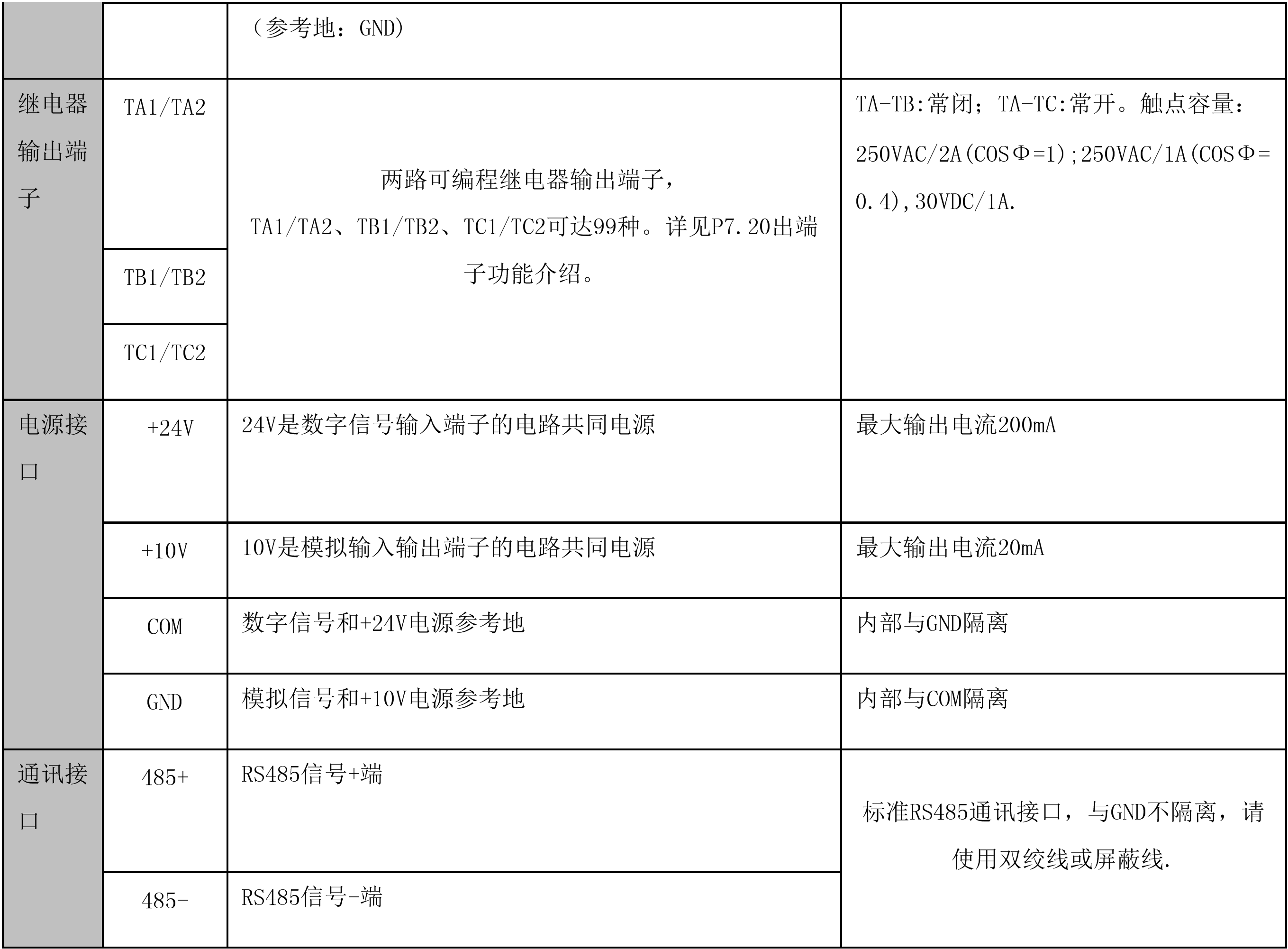

Control circuit terminal function table

▲ The control terminal AI1 can input voltage signals and current signals, while AI2 can only input voltage signals; the user should make the corresponding jumper selection on the main control board according to the signal type when using it.

▲ Connect weak analog signals, which are easily affected by external interference, so the wiring should be as short as possible. The external control line of the inverter needs to be equipped with an isolation device or a shielded line must be grounded.

▲ In addition to shielding, the wiring of the input command signal line and frequency meter should also be routed separately, preferably away from the main circuit wiring.

▲ The control circuit wiring should be larger than 0.75mm2, and shielded twisted pair wire is recommended. The connection of the control circuit terminal should be tin-lined or cold-pressed metal joints.

▲ When connecting an analog signal output device, sometimes it will malfunction due to the interference of the inverter. When this happens, connect a capacitor or a ferrite ring to the external analog output device.