1. Magnetic flux vector control, without self-learning, provides higher performance than ordinary V/F;

2. Aluminum alloy heat dissipation, easy disassembly of the heat dissipation fan, stable heat dissipation guarantee to adapt to complex working conditions such as dust and cotton wool;

3. Small size, saving customer installation space;

4. Standard LED keyboard with potentiometer and externally available;

5. The product design strictly follows the IEC national standard and meets the CE certification test requirements;

6. Automatic slip compensation-more accurate speed;

7. Automatic torque compensation—up to 150% when starting at 3HZ;

8. High overload capacity—150% rated torque can last for 60 seconds;

9. Ultra-low noise, the carrier frequency can be adjusted between 1-15K (depending on the model);

10. The control and protection are timely and reliable, and the system stability is high;

11. Set a variety of commonly used functions to meet application requirements:

(1) Standard Modbus communication

(2) Process PID control

(3) With 16 speed control

(4) 0~1000HZ high frequency output

(5) Multi-point V/F curve setting is possible

(6) Speed tracking function, automatically search for motor speed, and restart without stopping

(7) Single week and cycle counting function

(8) With multi-function input and output ports, and the switch value can be set to delay time

(9) It has protection functions such as over current, over voltage, under voltage, over temperature, overload, etc., and can save fault information

(10) There are multiple options for DC braking, magnetic flux braking, and resistance energy consumption braking

(11) Over-current stall, over-voltage stall, response to sudden load changes

(12) V/F curve can be adjusted according to load characteristics

(13) Pulse train I/O function

(14) Multi-speed control function

(15) Stop deceleration/restart after instantaneous power failure

(16) PID control function

(17) Communication function

(18) Main and auxiliary frequency input function

(19) One internal counter

(20) Torque detection function

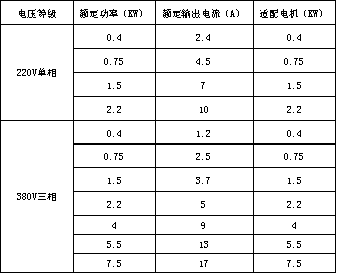

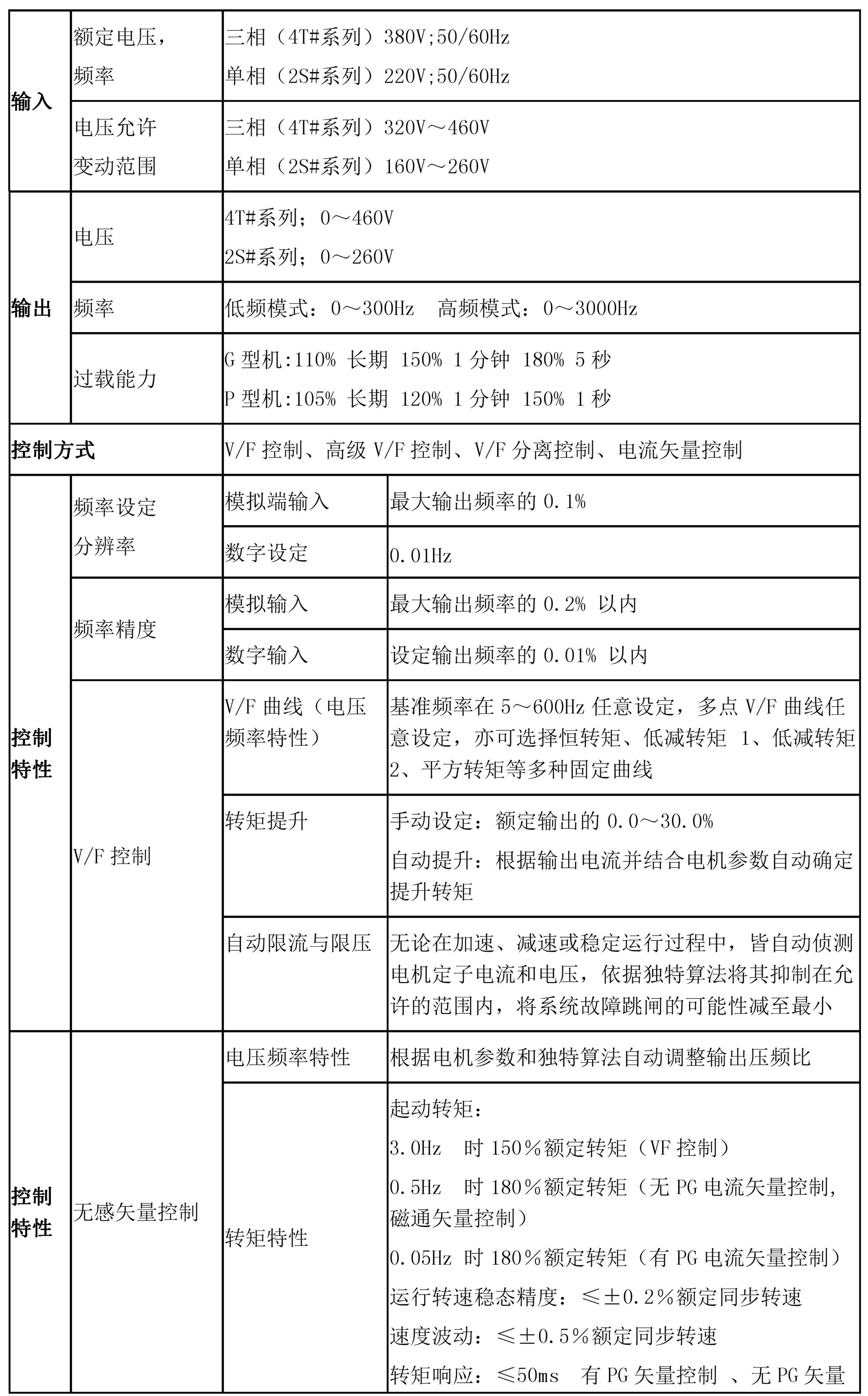

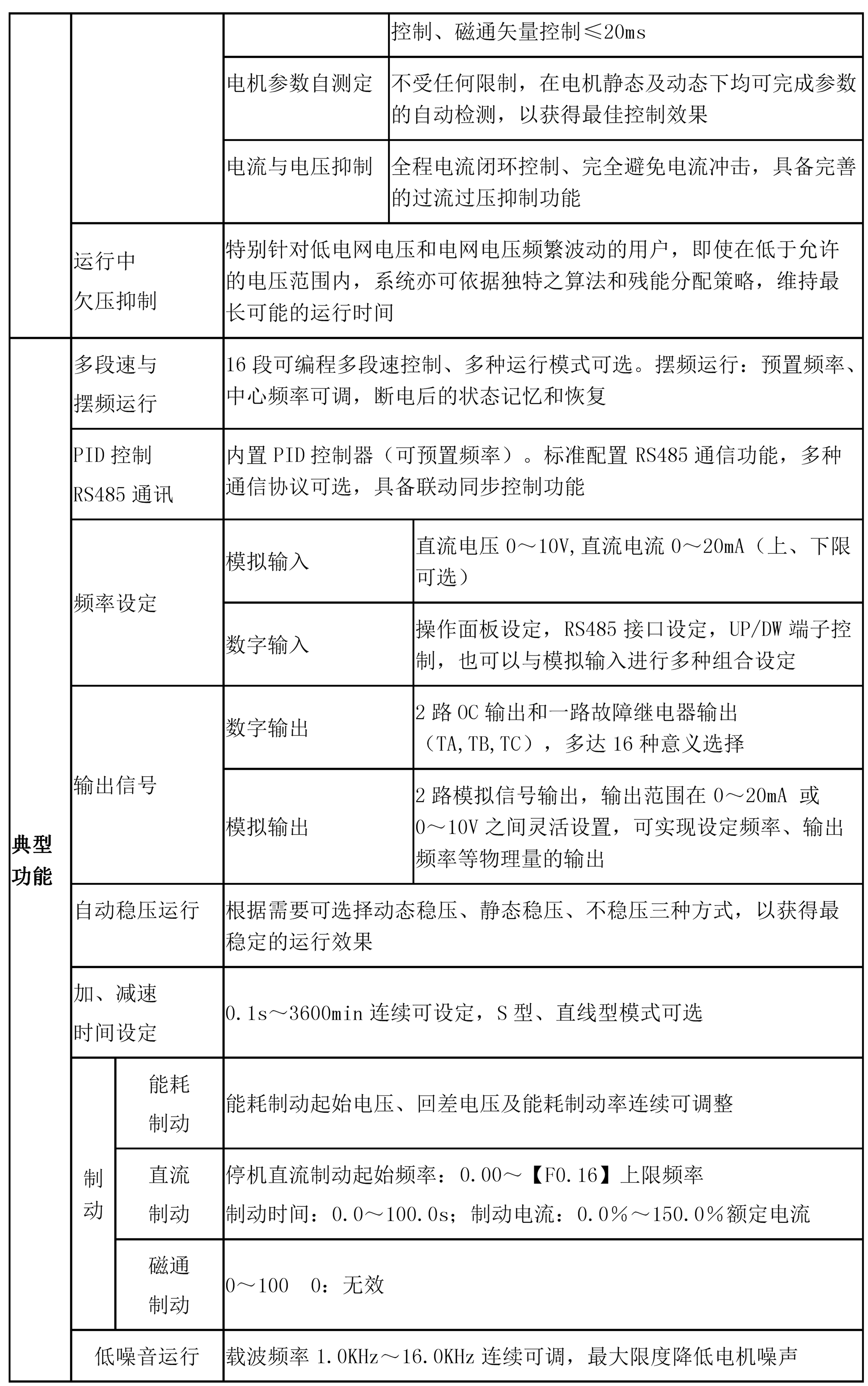

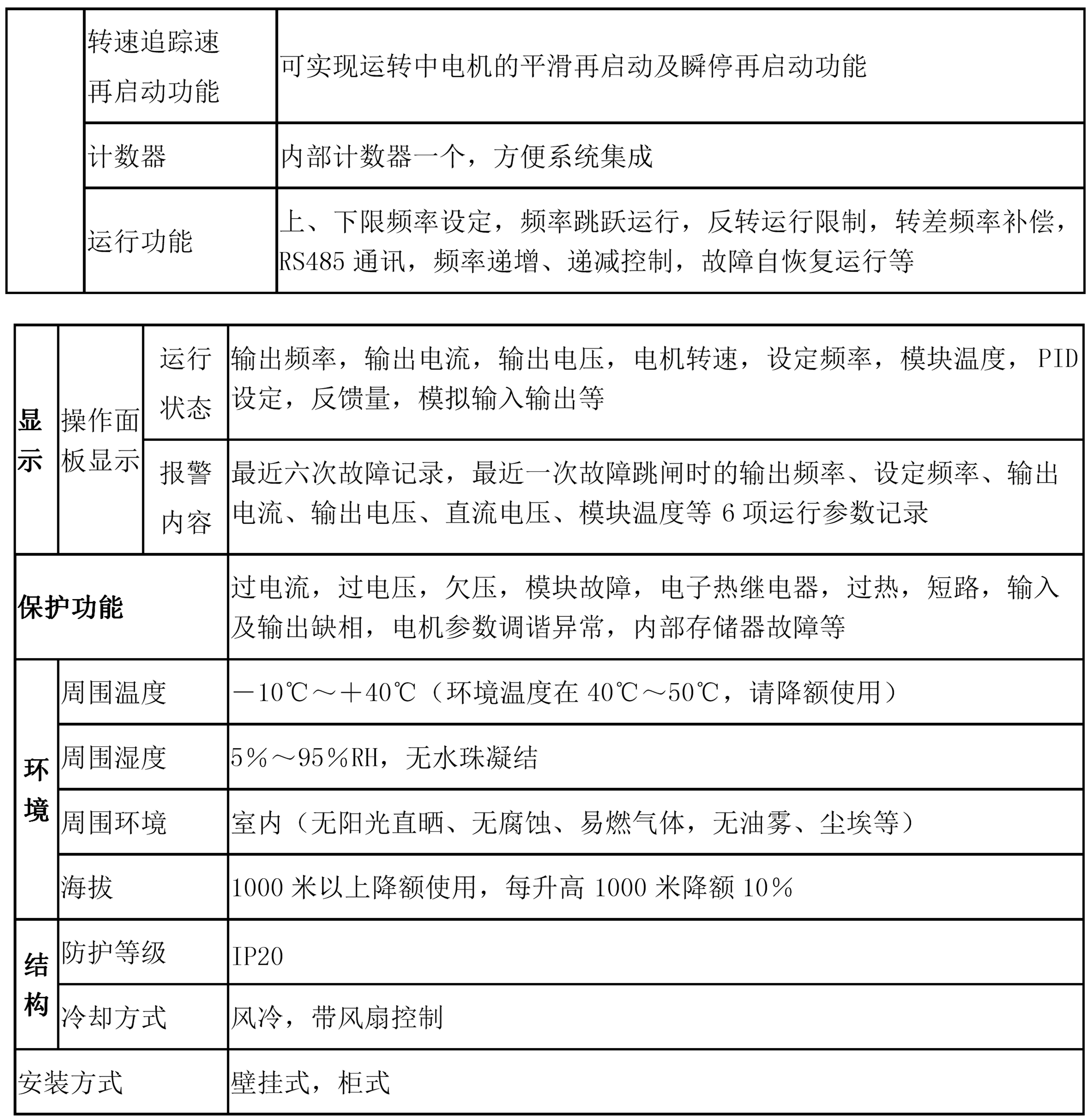

产品技术指标及规格:

Keyboard size

External keyboard opening size

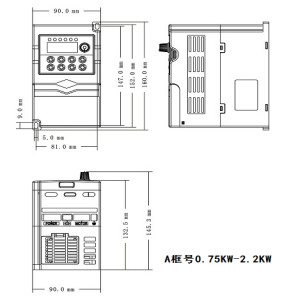

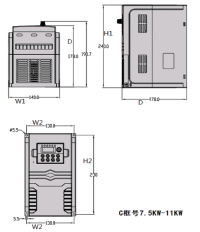

Product dimensions and installation dimensions A frame type (unit: MM)

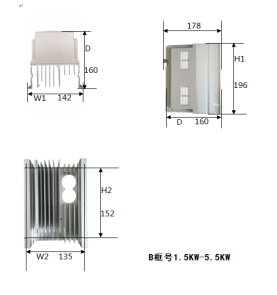

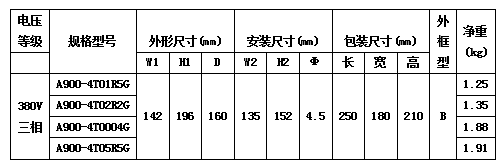

Product dimensions and installation dimensions B frame type (unit: MM)

Product dimensions and installation dimensions C frame type (unit: MM)

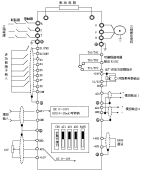

The inverter wiring part is divided into main circuit and control circuit. The user can lift the cover of the output/input terminal, and the main circuit terminal and the control circuit terminal can be seen at this time. The user must connect the wiring circuit correctly according to the figure below.

![]()

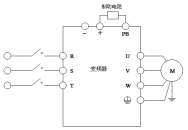

Main circuit terminal wiring

Schematic diagram of main circuit terminals

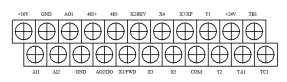

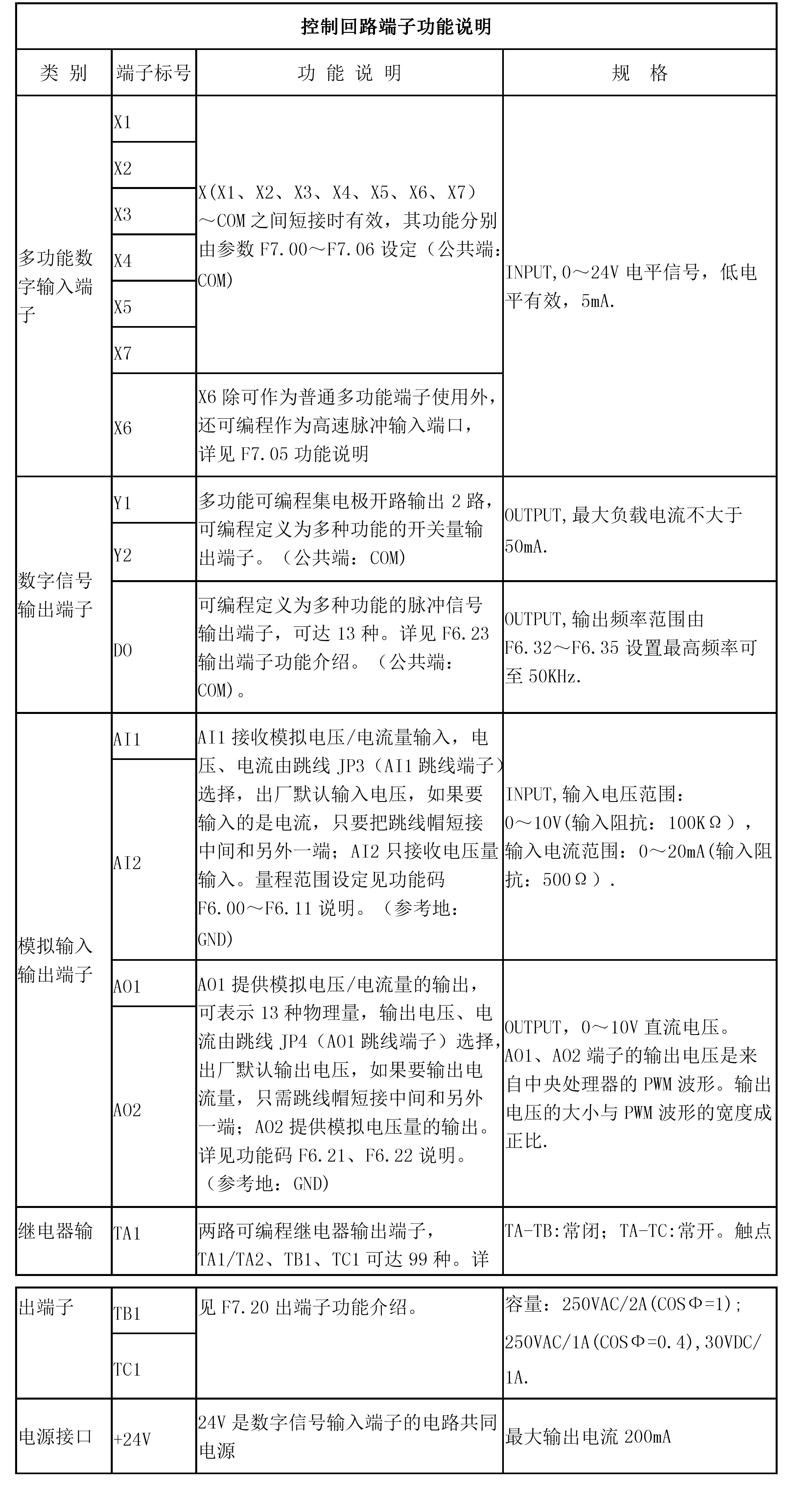

Schematic diagram of control circuit terminals

Control circuit terminal function table

▲ Control terminal AI1 can input voltage signal and current signal, while AI2 can only input voltage signal; the user should use it according to the signal type,

Make the corresponding jumper selection on the main control board.

▲ Connect weak analog signals, which are easily affected by external interference, so the wiring should be as short as possible. The external control line of the inverter needs to be equipped with isolation device or

Use shielded wire and grounding is required.

▲ In addition to shielding, the wiring of the input command signal line and frequency meter should also be routed separately, preferably away from the main circuit wiring.

▲ The control circuit wiring should be larger than 0.75mm2, and shielded twisted pair wire is recommended. The connection of the control circuit terminal should be tin-lined or cold-pressed metal joints.

▲ When connecting an analog signal output device, sometimes it may malfunction due to the interference of the inverter. When this happens, you can connect it to the side of the external analog output device.

Connect capacitor or ferrite magnetic ring.